|

| February 06, 2024 | Volume 20 Issue 05 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Lightweight structural ink could reduce plane paint weight 90%

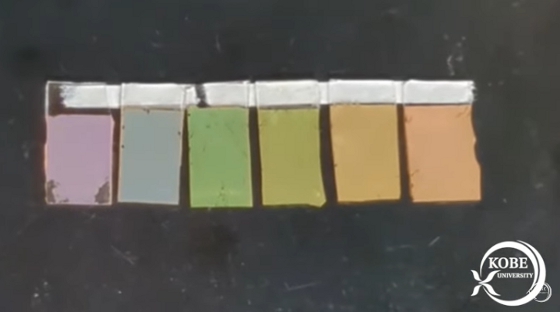

A single layer of silicon nanospheres produces bright structural colors that are independent of the viewing angle. [Credit: © FUJII Minoru (CC BY)]

A new way of creating color uses the scattering of light of specific wavelengths around tiny, almost perfectly round silicon crystals. This Kobe University (Japan) development enables non-fading structural colors that do not depend on the viewing angle and can be printed. The material has a low environmental and biological impact and can be applied extremely thinly, promising significant weight improvements over conventional paints.

An object has color when light of a specific wavelength is reflected. With traditional pigments, this happens by molecules absorbing other colors from white light, but over time this interaction makes the molecules degrade and the color fades. Structural colors, on the other hand, usually arise when light is reflected from parallel nanostructures set apart at just the right distance so that only light of certain wavelengths will survive while other wavelengths are cancelled out, reflecting only the color we see. This phenomenon can be seen in wings of butterflies or feathers of peacocks, and has the advantage that the colors don't degrade. However, from an industrial point of view, neatly arranged nanostructures cannot be painted or printed easily, and the color depends on the viewing angle, making the material iridescent.

VIDEO: The color of the silicon nanospheres can be controlled by the diameter of the spheres, where smaller particles are bluer and larger ones redder. [Credit: © FUJII Minoru (CC BY)]

Kobe University material engineers Fujii Minoru and Sugimoto Hiroshi have been developing an entirely new approach to producing colors. They explain, "In previous work since 2020, we were the first to achieve precise particle size control and develop colloidal suspensions of spherical and crystalline silicon nanoparticles. These single silicon nanoparticles scatter light in bright colors by the phenomenon of 'Mie resonance,' which allows us to develop structural color inks." With Mie resonance, spherical particles of a size comparable to the wavelength of light reflect specific wavelengths particularly strongly. This means the color that mainly comes back from the suspension can be controlled simply by varying the size of the particles.

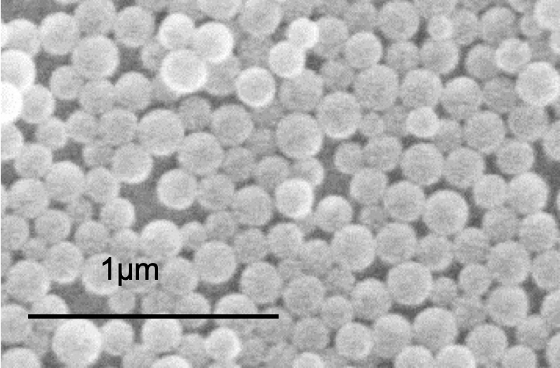

A scanning electron micrograph of the nanosphere monolayer shows almost perfectly round particles of uniform size and only small regions of voids or agglomerates. [Credit: © FUJII Minoru (CC BY)]

In their work published in the journal ACS Applied Nano Materials, Fujii and Sugimoto demonstrate how the suspension can be applied to surfaces, coating the material with a form of structural color that does not depend on the viewing angle. This is because the color is not produced by the interaction of light reflected from neighboring structures as with "traditional" structural colors, but by its highly efficient scattering around the individual nanospheres. Sugimoto explains another advantage: "A single layer of sparsely distributed silicon nanoparticles with a thickness of only 100 to 200 nanometers shows bright colors but weighs less than half a gram per square meter. This makes our silicon nanospheres one of the lightest color coats in the world."

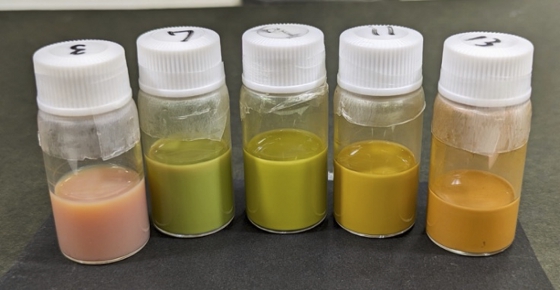

The nanospheres in a methanol suspension have different colors than when applied to a surface as a monolayer. The Kobe University researchers explain, "This is due to the multiple scattering, i.e., blue light subsides during consecutive scattering by absorption, while red light survives." [Credit: © FUJII Minoru (CC BY)]

The Kobe University team has used computational simulations to explore the properties of the ink under different circumstances, such as by varying the size of the particles and the distance between them, and then confirmed their results experimentally. They found that, contrary to intuition, the reflectance was highest when the individual particles were separated instead of when tightly packed. The authors explain, "This high reflectance despite small coverage of the surface by the nanospheres is due to the very large scattering efficiency. The requirement of a very small amount of silicon crystals for coloration is an advantage in the application as a color pigment."

After further development and refinements, they foresee interesting applications of their technology. Sugimoto explains, "We can apply it to the coating of, for example, airplanes. The pigments and coatings on an airplane have a weight of several hundreds of kilograms. If we use our nanosphere-based ink, we might be able to reduce the weight to less than 10% of that."

Source: Kobe University

Published February 2024

Rate this article

View our terms of use and privacy policy